Synthetics, Simulants & Enhancements

Natural diamonds have formed naturally within the earth. Synthetic diamonds are created by a man-made process. A diamond simulant is defined as a non-diamond material that is used to simulate the appearance of a diamond. Diamond-simulant gems are often referred to as diamante.

The gemmological and industrial uses of diamond have created a large demand for rough stones. The demand for industrial diamonds has long been satisfied in large part by synthetic diamonds, which have been manufactured by various processes for more than half a century. However, in recent years it has become possible to produce gem-quality synthetic diamonds of significant size.

The majority of commercially available synthetic diamonds are yellow in colour and produced by so called High Pressure High Temperature (HPHT) processes. The yellow colour is caused by nitrogen impurities. Other colours may also be reproduced such as blue, green or pink which are a result of the addition of boron or from irradiation after synthesis.

At present the annual production of gem quality synthetic diamonds is only a few thousand carats, whereas the total production of natural diamonds is around 120 million carats. Although the production of colourless synthetic diamonds is dwarfed by that of natural diamonds, one can only find one fancy coloured diamond for every 10.000 colourless ones. Since almost the complete production of synthetic diamonds consists of fancy diamonds, there is a high probability that the larger fancy coloured diamonds (over 1.5 carats) will be synthetic.

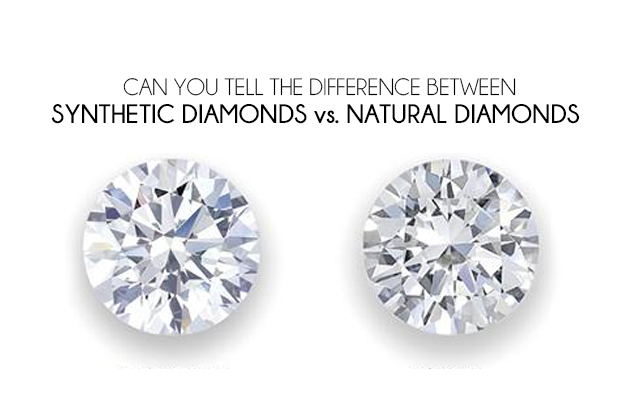

Today, trained gemmologists can generally also distinguish between natural diamonds and synthetic diamonds. Although synthetic and natural diamonds are theoretically identical and indistinguishable from each other, diamonds from each of the two categories usually incorporate their own characteristic imperfections, arising from the circumstances of their creation, that allow them to be distinguished from each other. In the case of synthetic diamonds, for example, depending on the method of production and the colour of the diamond, several methods of identification can be attempted by

a gemmologist or gem lab: CVD diamonds can usually be identified by an orange fluorescence, D-J coloured diamonds can be screened through the Swiss Gemmological Organization’s Diamond Spotter, and stones in the D-Z colour range can be examined through the DiamondSure UV/visible spectrometer developed by De Beers.

Similarly, natural diamonds usually have minor imperfections and flaws, such as inclusions of foreign material, that are not seen in synthetic diamonds. The origin of a truly perfect diamond (natural or synthetic) cannot be determined and is largely moot, but perfect diamonds are currently rare from both sources.

A diamond’s gem quality, which is not as dependent on material properties as industrial applications, has invited both imitation and the invention of procedures to enhance the gemmological properties of natural diamonds. Materials which have similar gemmological characteristics to diamond but are not mined or synthetic diamond are known as diamond simulants. The most familiar diamond simulant to most consumers is cubic zirconia (CZ); recently moissanite has also gained popularity and has often been mischaracterized as a diamond simulant, although it is sold and retailed as a replacement for diamond. Both CZ and moissanite are synthetically produced. However, CZ is a diamond simulant.

Diamond enhancements are specific treatments, performed on natural diamonds (usually those already cut and polished into a gem), which are designed to better the gemmological characteristics of the stone in one or more ways. These include laser drilling to remove inclusions, application of sealants to fill cracks, treatments to improve a white diamond’s colour grade, and treatments to give fancy colour to a white diamond.

Currently, trained agi gemmologists with appropriate equipment are able to distinguish natural diamonds from simulant diamonds, and they can identify all enhanced natural diamonds. Coatings are more and more used to give a diamond simulant such as cubic zirconia a more “diamond-like” appearance.

One such substance, which is heavily advertised, is what scientists refer to as “diamond-like carbon”. This is an amorphous carbonaceous material that has some physical properties which are similar to that of the diamond. Advertising suggests (righfully so or not) that such a coating would transfer some of these diamond-like properties to the coated stone, hence enhancing the diamond simulant. However, modern techniques such as Raman Spectroscopy should easily identify such as treatment.

Producing large synthetic diamonds threatens the business model of the diamond industry, and the ultimate effect of the ready availability of gem-quality diamonds at low cost in the future is hard to predict at this time.